Abstract:An yi nazarin tsarin ƙirƙirar da haɗarin lubricating mai varnish: Ka'idar cire varnish ta hanyar haɗin cajin tacewa da resin musanya an gabatar da shi Dandali Hanyar da kayan aiki suna da tasiri mai kyau akan inganta tsabtar man fetur da kuma kawar da gurɓataccen gurɓataccen abu.

Mahimman kalmomi:injin turbine; lubricating mai varnish; gwajin MPC; cajin tacewa; canjin guduro

Injin iskar gas yana ɗaya daga cikin ainihin kayan aikin dandamalin teku.Ana amfani da shi azaman kayan aikin samar da wutar lantarki akan dandamalin ketare don tabbatar da kwanciyar hankali da tsayin daka na aikin injin turbin gas don tabbatar da samar da dandamali na yau da kullun na ketare.Gilashin iskar gas yana cikin yanayin zafi mai zafi, matsa lamba da sauri yayin aiki, kuma varnish yana da sauƙin samar da shi a cikin wannan yanayin.A lokaci guda, tare da haɓaka ingantaccen ingancin mai a cikin lubricating mai, ikon lubricating mai narkar da varnish ya lalace, wanda kuma yana haɓaka saurin samuwar varnish.Samar da varnish yana haifar da tarawar varnish, babban cutarwa ga kayan aiki, zai haifar da raguwar sharewa, ƙãra lalacewa, bawul core adhesion kayan aiki aiki ne m har ma da kasawa;varnish da aka ajiye akan shaft, mai sanyaya da sauran abubuwan da aka gyara suna haifar da canjin yanayin zafi na shaft mai sanyaya zafi musayar zafi, haɓakar iskar shaka mai: varnish zai haɗe zuwa ƙwararrun ƙwayoyin cuta, toshe ɓangaren tacewa da rami mai maƙarƙashiya, yana haifar da lalacewa kayan aiki da kayan aiki mara kyau. lubrication, na cikin gida da na waje turbin gas mara kyau fenti rufe yana faruwa.A cikin wannan takarda, marubucin ya gabatar da matsalolin da ba a saba da su ba kamar gano halin dandali na Huizhou 32-2 na injin samar da iskar gas mai amfani da hasken rana, ya tattauna aikace-aikace nanaúrar cire varnisha cikin rukunin dandamali, kuma yana ba da wasu tunani don ma'aikatan kula da kayan aiki a cikin masana'antu masu alaƙa a cikin sarrafa kayan aikin lubricating mai varnish.

1 Tsarin tsari da haɗari na lubricating mai varnish

1.1 Nazarin lubricating mai fim

varnish shine polymer, shine iskar oxygenation na abubuwan mai, launi daga launin ruwan kasa mai haske, launin ruwan kasa zuwa tan, tsarar sa na babban dalilin akwai bangarori uku.

(1) Oxidative da lalata samfuran mai: ana amfani da samfuran mai a cikin hanya.Babban yanayin zafi, ruwa, karafa, da iska duk suna hanzarta iskar shaka, don samar da carboxylic acid, ester, barasa da sauran samfuran oxidation, da ƙarin nau'in haɓakawa cikin polymer: ƙari, amine antioxidant a cikin mai kuma yana da sauƙin samar da varnish.

(2) Wuraren zafi na cikin gida da bustion na microcom suna haifar da tushe mai tushe ko saurin lalata abubuwan ƙari don samar da varnish, zafin jiki mai ƙarfi ko ƙarfin ƙarfi Sashe na saman ƙarfe a zazzabi mafi girma (na kowa kamar ɗaukar daji), yana haifar da Yanayin zafin ruwan da ke tuntuɓar wurin yana da girma sosai, yana haifar da lalatawar yanayin zafi mai sauri don samar da varnish, kuma cikin sauƙi manne da waɗannan abubuwan Samuwar tarawa;lubricating man a cikin hali na kaifi matsawa ne kuma sauki don samar da micro konewa sabon abu, don samar da wani sosai kananan size na insoluble abu, a haɗe da karfe surface samar da wani varnish, idan aka kwatanta da na farko ƙarni na hadawan abu da iskar shaka lalata, na biyu ƙarni na fenti Gudun membrane zai yi sauri da sauri.

(3) Fitar da tartsatsin kuma zai haifar da varnish, musamman lokacin da mai ya ratsa ta wani nagartaccen nau'in tacewa don samar da tsayayyen halin yanzu, lamarin fitar da tartsatsin yana haifar da tarin varnish cikin sauki.

1.2 Haɗarin lubricating mai varnish

Varnish tarawa a kan gogayya gefen surface zai rage man fim rata, zafi dissipation canji matalauta, da lubricating man fluidity deterioration, haifar da gogayya karin surface zafin jiki zuwa gagarumin Yunƙurin High, mai tsanani lalacewar lamba surface;injin turbin gas koyaushe yana buɗewa kuma yana dakatar da yanayin aiki, canjin yanayin zafin mai yana iya haifar da sifar varnish, varnish da aka kafa zai iya sauƙi manne da abubuwan da suka dace, kamar bawul ɗin servo na hydraulic, yana haifar da toshe bawul, bawul. core bond card mutu, sarrafa gazawar har ma kayan tsalle;Har ila yau, varnish yana haifar da sakamako mai sanyaya sanyi mara kyau, toshewar kashi mai tsarkakewa, ƙarancin lubrication yana ƙara lalacewa da haɓaka iskar oxygen samfurin mai da sauran sakamako.

2 Ma'auni na gano maƙasudin ƙididdigewa

A halin yanzu, hanyar auna ma'auni mai lanƙwasa mai shine ASTM D7843 "ganewar bincike na hoto na hoto (MPC) don amfani da hanyar gwaji don kayan da ba a iya narkewa a cikin mai turbine.An bayar da rahoton sakamakon a matsayin ma'aunin halayen Paint Membrane AE.Ka'idar wannan hanyar ita ce ta amfani da tsarin tsaftacewa mai tsabta Cire sludge da gelatin daga samfurin mai kuma saka shi a cikin membrane mai tsabta mai tsabta A kan farantin (0.45 p, m) mai tsabta, yi amfani da mai tsaftacewa bayan an bushe farantin mai tsabta. Gwajin chromaticity na fim don gwada ƙimar MPC (AE).An ajiye membrane mai tsarkakewa Yawan abubuwan da kuke samu.Da duhu launi, mafi girma da varnish hali index.Idan aka maimaita

Ci gaba da haɓaka ƙimar MPC (AE) yakamata ya sa ma'aikatan manajan kayan aiki ko ma'aikatan kulawa su kula da shi.

3. Aikace-aikace na cirewar mai tsarkakewa

3.1 Matsayi na yanzu na mai mai mai kafin amfani da mai cire mai mai tsarkakewa

Huizhou 32-2 dandali na iskar gas injin janareta saitin Solar T60 naúrar,

Dubi Tebu 1 don ƙayyadaddun ƙayyadaddun sigogi na man mai kafin amfani da mai tsarkakewa.

| Table 1 Bayanan gwaji na man turbine kafin tacewa | ||

| Aikin | Bayanan tsarkakewa | Ƙimar magana |

| samfurin tanki / iya aiki | Ƙarfin vortex 46 # mai / kowace naúrar kusan 1800L | / |

| Dankin motsi na 40 ℃ V / (mm² s- ¹ | 45.37 | 41.4-50.6 |

| Ƙimar acid (a cikin KOH) w/ (mg·g-¹) | 0.18 | ≤0.35 |

| Danshi c/(mg·L-¹) | 46 | ≤100 |

| tsabta ISO | 23/21/11 | ≤–/16/13 |

| Indexididdigar haɓakawa ta varnish / MPC | 31.5 | ≤20 |

Ƙarshe na hukumar gwaji na ɓangare na uku shine kamar haka: babban ma'anar ma'anar varnish mai daraja tebur mai haske mai haske yana ƙunshe da adadi mai yawa na polar ƙananan ƙwayoyin ƙwayoyin da ba za a iya narkewa ba, mai sauƙi don manne wa karfe yana samar da varnish a saman, varnish zai haifar da gogayya. zafin jiki na biyu don tashi da haifar da gazawar kayan aiki, babban abun ciki mai mahimmanci zai iya rinjayar kwanciyar hankali da tsarin tsarin sabis na ɓangaren da ke da alaƙa, ana iya ci gaba da amfani da man fetur, amma ana buƙatar babban aikin tacewa.Yi amfani da kayan aikin cire varnish don cire polarity daga mai narkewar mai, ana ba da shawarar gajarta lokacin samfur kuma kula da tsabta da ƙimar MPC da sakamakon saka idanu.Ta hanyar lura a wurin kayan aiki, lubricating mai kula da matsa lamba na rashin zaman lafiya yana faruwa a cikin aiki, wanda ke da matukar tasiri ga amincin tsarin man fetur da aka shirya da kuma abubuwan sarrafa ruwa.

3.2 Ka'ida da aikace-aikace nanaúrar cire varnish

Bisa la'akari da matsalar varnish a cikin man shafawa, wasu kamfanoni sun ɗauki matakan canza mai, amma tasirin bai dace ba kuma ba kare muhalli ba.Don tabbatar da cewa janareta saita Amintaccen, yanke shawarar shirya aikin cirewar varnish da aikin tacewa.

Ka'idodin fasaha na wakilai da yawa na masu tsabtace mai ana yin su a cikin Tebu 2

kwatancen bincike.

Cikakken kwatancen bincike yana ƙayyade adsorption na caji + itacen musanya

Fasahar lipid don cire varnish daga mai.Ta wurin ainihin gwajin, na zaɓi ɗaya

A WVD mai tsaftataccen man fenti mai tsafta, mai tsabtace mai tattara cajin tallan fasahar tsarkakewa da fasahar tallan resin a daya, ta hanyar bishiyar musanya ce.

Ana cire samfuran varnish kuma an narkar da su ta hanyar fasahar tallata caji

Cire fenti da aka dakatar da shi daga mai da abubuwan da aka haɗa fim ɗin.

| Table 2 Bambance-bambancen fasahar rigakafin varnish daban-daban | |||

| Siffar Varnish | Musanya fasahar guduro | Cajin fasahar tallatawa | Cajin adsorption + musayar fasahar guduro |

| Narkar da varnish a cikin maganin mai | Cire da guduro adsorption | Ba za a iya cirewa ba | Cire da guduro adsorption |

| An dakatar da varnish a cikin mai | Cire ta hanyar dabarar rushewar guduro | Cire ta hanyar tallan tallan caji | Cire ta hada cajin tacewa da kuma fasahar rushewar guduro |

| varnish da aka haɗe zuwa daji mai ɗaukar hoto da abubuwan da aka gyara | Cire ta hanyar dabarar rushewar guduro | Za a iya cire varnish ɗin da aka makala da ƙarfi ta hanyar ɓangarorin da aka caje

| Ana cire varnish ɗin da aka makala ta hanyar haɗa ɓangarorin da aka caje da fasahar rushewar guduro |

| Cikakken kimantawa | Dogaro da guduro don cire varnish mai narkewa, sa'an nan kuma cire narkar da varnish da abubuwan da aka gyara na varnish ta hanyar ka'idar rushewar mai na dogon lokaci, ingantaccen aiki yana da ƙasa, kuma abubuwan da ake amfani da su na resin a cikin lokacin baya suna da nauyi. | Za a iya cire varnish da aka dakatar kawai a cikin mai da varnish da aka haɗe zuwa abubuwan da aka gyara, saboda tasirin narkar da varnish bai dace ba. | Cajin adsorption tace fasahar hade tare da guduro adsorption fasaha ba zai iya kawai sauri cire narkar da varnish, amma kuma iya sauri cire man da aka dakatar da varnish da aka gyara na haɗe varnish, high dace, low marigayi itace manufa ulu abu. |

3.2.1 Cajin fasahar talla da ka'idar aiki

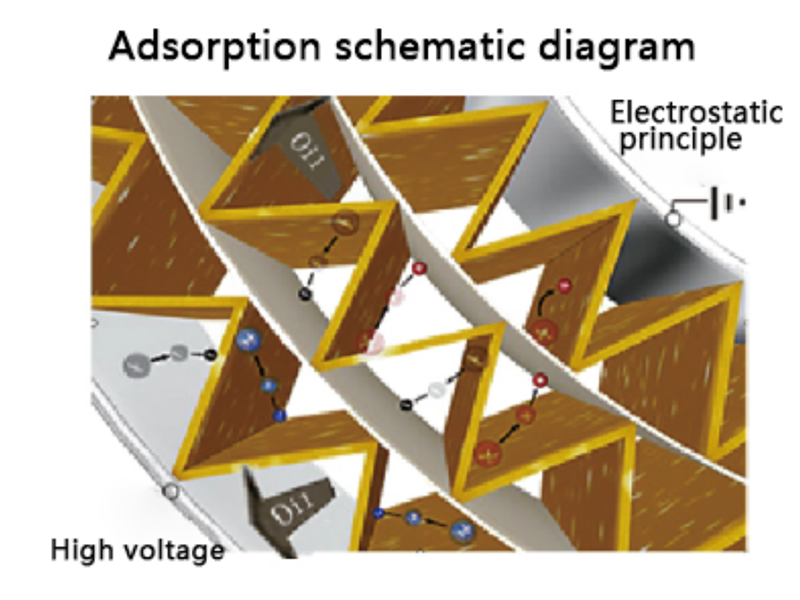

Cajin adsorption fasaha yafi amfani da babban ƙarfin lantarki janareta don samar da high irin ƙarfin lantarki a tsaye filin lantarki, sa gurbatawa barbashi a cikin man polarized da kuma nuna tabbatacce da korau wutar lantarki bi da bi, m da korau lantarki barbashi suna daidai da a karkashin mataki na matsananci-high irin ƙarfin lantarki. Filayen lantarki Rarrabu masu kyau da masu inganci suna iyo, kuma tsaka-tsakin tsaka-tsakin suna matsi da kwararar ɓangarorin da aka caje.A karshe, duk barbashi suna adsorbed da kuma haɗe zuwa ga mai tarawa, Kuma ta hanyar wani ɓangare na cajin man fetur barbashi da cewa ba su da lokaci zuwa sha da kwarara, za Mlay impurities, varnish da hadawan abu da iskar shaka a haɗe da man tanki, bututu bango da kuma aka gyara.

Duk abubuwan suna wanke bandejin adsorption (duba Hoto 1).Wannan dabarar na iya zama mai tasiri wajen share varnish da aka dakatar da varnish da aka haɗe zuwa abubuwan da aka gyara, don ɗagawa

Tsabta mai girma kuma yana da sakamako mai kyau.

3.2.2 Daidaitaccen fasaha tsarkakewa caji

Daidaitaccen fasahar tsarkakewa ta caji (Balanced Charge purification) Hanyar ita ce rarraba ruwan da ke ɗauke da ƙananan barbashi zuwa rassa biyu.Reshe Hanyar tana sanye take da na'urorin lantarki masu ƙarfi don ɗaukar ingantaccen caji da ƙananan barbashi bi da bi mara kyau: sannan auna magudanar ruwa biyu tare da ɓangarorin caji.

Sabuwar tarawar matasan.Zarge-zarge masu kyau da mara kyau suna jawo hankalin juna kuma su taru don samar da babban mai mulki 10 inch barbashi;ƙarewa da injina ko centrifugal purifier Inci na ƙãra barbashi.

3.2.3 Musanya fasahar tallan guduro

Ba shi yiwuwa ga narkar da kayayyakin varnish su dogara da cajin adsorption fasahar

almubazzaranci.Kayan aikin guduro na musamman shine narkar da samfurin varnish (wanda kuma ake kira lacquer film amfrayo) yana ba da matsakaicin matsakaicin kusanci, ta amfani da guduro Rukunin asali masu wadata akan kayan talla na iya tallata kowane nau'in samar da lalata da kyau sosai.Don haka yana da babban adadin cirewar samfuran varnish.Abun adsorption na resin Kyakkyawan kwanciyar hankali na kayan abu, juriya mai zafi, amfani ba zai sami samfuran lalata ba kuma ya faɗi abubuwa sun shiga cikin mai.Bugu da ƙari, yin amfani da fasaha na rushewar resin resin (dogara da itacen Bayan lipid ya cire fim din da aka narkar da shi a cikin mai, fim din da aka dakatar a cikin man fetur da kuma haɗe tare da varnish a kan abubuwan da aka gyara zai juya baya narkar da man a cikin wani narkar da man fetur). varnish, Sa'an nan kuma cire ta hanyar resin adsorption), don mai a cikin yanayin dakatarwa da kuma haɗe A cikin abubuwan da ke cikin varnish kuma yana da wani tasirin cirewa.

3.2.4 Takamaiman tasirin aikace-aikacen cire mai tsarkakewa na varnish

Ta hanyar WVD bayyanannen mai tsabtace varnish a dandalin 32-2 Solar Naúrar T60 ta gudanar da tsarkakewa ta sake zagayowar kan layi na kusan kwanaki 10.Zuwa ingantaccen maganin mai Ana nuna bayanan gwajin samfuri a cikin Tebura 3.

| Table 3 Bayanan gwaji na mai turbine bayan tacewa | ||

| Aikin | Bayanan tsarkakewa | Ƙimar magana |

| samfurin tanki / iya aiki | Ƙarfin vortex 46 # mai / kowace naúrar kusan 1800L | / |

| Dankin motsi na 40 ℃ V / (mm² s- ¹ | 45.43 | 41.4-50.6 |

| Ƙimar acid (a cikin KOH) w/ (mg·g-¹) | 0.12 | ≤0.35 |

| Danshi c/(mg·L-¹) | 55 | ≤100 |

| tsabta ISO | 15/13/9 | ≤–/16/13 |

| MPC | 4.4 | ≤20 |

An samo ta hanyar hukumar gwajin mai na ɓangare na uku.lube Bayan tsarkakewa, ɗabi'a da tsaftar index na fim ɗin kafin tsarkakewa a bayyane yake Ingantawa, ƙimar acid kuma ta ragu sosai;ko da yake ruwan ya ɗan ƙara kaɗan, amma la'akari da cewa kuskuren ganowa da sauran abubuwan har yanzu suna cikin kewayon da ya dace, don haka ba a la'akari da shi azaman tushen gwaji;duk sauran alamomin al'ada ne, kuma ƙarshen gwajin ya cancanci.A lokaci guda bayyana Matsakaicin sarrafa man mai mai lubricating ba shi da kwanciyar hankali yayin aiki na tsarkakewar varnish Babban haɓakawa, kuma tasirin yana bayyane.

4 Kammalawa

Hanyar haɗa cajin caji da na'urar guduro na musanya na iya inganta haɓakar turbin iskar gas mai ma'aunin mai da ma'aunin ƙazanta.Shigar da rukunin T60 na Solar a cikin dandamali na 32-2 bayan amfani da tsabtace mai cirewar varnish tare da jerin WVD.Rukunin lubricating man varnish propensity Manuniya da tsabta an inganta su kuma an dawo da su zuwa kewayon da suka cancanta, sun sami tasirin da ake so, hana samuwar varnish, wasu na zahiri da sinadarai Hakanan index ya inganta, musamman ma'aunin sarrafa mai a cikin rukunin. An kuma kawar da lamarin rashin kwanciyar hankali na karfi, tare da tabbatar da daidaiton aiki na sashin.Bugu da ƙari, sashin cirewar varnish yana aiki da ƙarfi a cikin yanayi mai tsauri, tasirin yana bayyana a fili, ƙarancin kayan masarufi yana da ƙasa, yana da amfani mai kyau.

Lokacin aikawa: Maris 15-2023