1 Bayani

Fasaccen injin damfarar iskar gas da tuƙi mai tuƙi na 100Kt/a ethylene sashen samarwa na Bora LyondellBasell Petrochemical Co., Ltd. duk sanye take da kayan aiki daga masana'antar Mitsubishi Heavy na Japan.

The pyrolysis gas compressor ne mai uku-Silinda biyar mataki 16-mataki impeller centrifugal kwampreso da 6 tsotsa tashar jiragen ruwa da 5 fitarwa tashar jiragen ruwa.Babban sigogin aiki sune kamar haka;Matsakaicin saurin shine 4056r/min, ƙarfin da aka ƙididdige shi ne 53567KW, ƙarfin fitarwa na kwampreso shine 3.908Mpa, zafin fitarwa shine 77.5 ° C, ƙimar kwarara shine 474521kg / h.Tuki turbine mai ɗaukar naúrar shine nau'in ƙwanƙwasa nau'in Kingbury tare da pads 6.Wadannan bearings an sanye su da rukunoni 6 na guraben man mai mai lubricating don lubricating, kuma kowane rukuni na mai yana da ramin shigar mai 4 3.0mm da 5 A 1.5mm, izinin axial tsakanin abin turawa da farantin turawa shine 0.46-0.56mm.Ɗauki hanyar lubrication tilas na samar da mai a tsakiya a tashar mai mai mai.

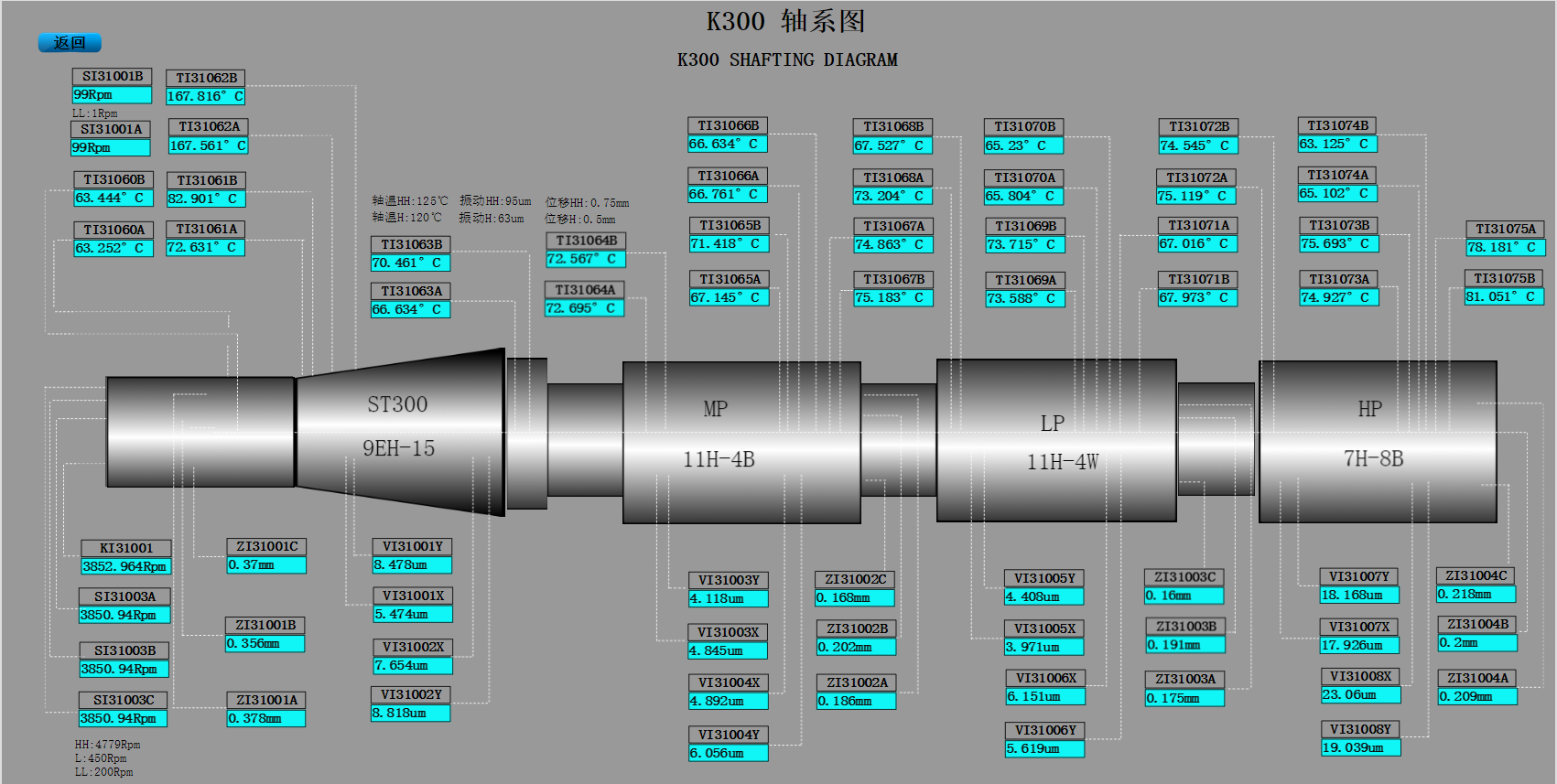

Jadawalin axis shi ne kamar haka:

2, Matsalar raka'a

Tun daga farkon naúrar kwampreso a ranar 5 ga Agusta, 2020, zazzabin turɓaya mai ɗauke da TI31061B na injin tururi ya ƙaru akai-akai, kuma a hankali ya ƙaru.Tun daga 16:43 ranar 14 ga Disamba, 2020, zafin jiki na TI31061B ya kai 118°C, wanda ke nesa da ƙimar ƙararrawa mintuna 2 kacal.℃.

Hoto 1: Yanayin turbin turbine mai ɗaukar zafin jiki TI31061B

3. Sanadin bincike da matakan magani

3.1 Abubuwan da ke haifar da canjin zafin jiki na turbine mai tururi mai ɗauke da TI31061B

Bayan dubawa da kuma nazarin yanayin canjin yanayin zafin jiki na turɓayar motsin turbine TI31061B, da kuma ban da matsalolin nunin kayan aiki a kan shafin, canjin tsari, goga na turbine, saurin kayan aiki, da ingancin sassa, manyan dalilan da ke haifar da shaft. canjin yanayin zafi sune:

3.1.1 Man mai da ake amfani da shi a cikin wannan kwampreso shine SHELL TURBO T32, wanda shine mai ma'adinai.Lokacin da zafin jiki ya yi girma, man mai da ake amfani da shi yana oxidized, kuma samfuran oxidation suna taruwa a saman daji mai ɗaukar hoto don samar da varnish.Man lubricating na ma'adinai galibi ya ƙunshi hydrocarbons, waɗanda ba su da ƙarfi a yanayin zafi da ƙarancin zafi.Duk da haka, idan wasu (ko da ƙananan adadin) na kwayoyin halitta na hydrocarbon sun sami halayen iskar oxygen a yanayin zafi mai yawa, sauran kwayoyin halitta na hydrocarbon kuma za su fuskanci halayen sarkar, wanda shine halayyar halayen sarkar hydrocarbon.

3.1.2 Lokacin da aka ƙara man lubricating zuwa kayan aiki, yanayin aiki ya zama yanayin zafi mai zafi da matsa lamba, don haka wannan tsari yana tare da haɓakar haɓakar iskar oxygen.A lokacin aiki na kayan aiki, saboda turbine ture bearing yana kusa da tururi mai matsananciyar matsananciyar zafi, zafin da ake samu ta hanyar zafi yana da girma.A lokaci guda, ƙaurawar axial na compressor ya kasance mai girma tun lokacin da aka fara shi, ya kai 0.49mm a lokaci guda, yayin da ƙimar ƙararrawa ta kasance ± 0.5mm.Ƙaƙwalwar axial na rotor turbine na tururi yana da girma da yawa, don haka adadin iskar oxygen na wannan ɓangaren motsa jiki na iya ninka sau biyu fiye da adadin iskar oxygen na wasu sassa.A cikin wannan tsari, samfurin oxidation zai kasance a cikin yanayi mai narkewa, kuma samfurin oxidation zai yi hazo lokacin da aka kai cikakken yanayin.

3.1.3 varnish mai narkewa yana haɓaka don samar da varnish mara narkewa.Lubricating man yana samar da varnish mai narkewa a cikin yanayin zafi mai zafi da matsanancin zafi.Lokacin da man fetur ya gudana daga yanayin zafi mai zafi zuwa ƙananan zafin jiki, zafin jiki yana raguwa kuma mai narkewa ya ragu, kuma ƙwayoyin varnish sun rabu da man shafawa kuma suna fara ajiya.

3.1.4 Zubar da varnish yana faruwa.Bayan an samar da ɓangarorin varnish, sai su fara haɓakawa kuma su samar da adibas waɗanda suka fi dacewa a ajiye su a saman saman ƙarfe masu zafi.A lokaci guda kuma, tun lokacin da zafin jiki ya kasance mai girma tun lokacin da aka fara aiki, yanayin zafin jiki a nan ya tashi da sauri yayin da zafin jiki na sauran bearings ya canza a hankali.

3.2 Magance matsalar hawan zafin jiki na turbine turbi mai ɗauke da TI31061B

3.2.1 Bayan gano cewa zazzabi na tura mai ɗauke da TI31061B ya tashi sannu a hankali, an rage zafin mai mai mai daga 40.5 ° C zuwa 38 ° C, kuma an ɗaga matsin man mai daga 0.15Mpa zuwa 0.176Mpa don sauƙi. jinkirin tashin zafin daji mai ɗaukar nauyi.

3.2.2 The turbine rotor yana da 15 matakai na impellers, na farko 12 matakai na impellers da ma'auni ramukan, da kuma na karshe 3 matakai ba a tsara tare da ma'auni ramukan.Gefen ƙwanƙwasa axial wanda Mitsubishi ya ƙera ya yi ƙanƙanta sosai, don haka daidaita injin injin tururi don daidaita matsawar axial.Kamar yadda aka nuna a cikin Hoto 2 1279ZI31001C, ƙaurawar injin injin tururi shine 0.44mm.Bayan tuntuɓar masana'anta na kwampreso, ƙaurawar shaft yana da kyau, wanda ke nufin cewa rotor yana canzawa zuwa gefen kwampreso dangane da na'ura mai ƙira ta asali, don haka an yanke shawarar rage matsakaicin hakar iska daga 300T / h Rage zuwa 210T / h. ƙara nauyi a gefen ƙananan matsa lamba na turbine, ƙara matsawa a kan babban matsa lamba, da kuma rage ƙarfin axial a kan abin da ke motsawa, ta haka ne ya rage girman yanayin hawan zafin jiki.

Hoto 2 Dangantaka tsakanin guguwar magudanar turbi da turawa

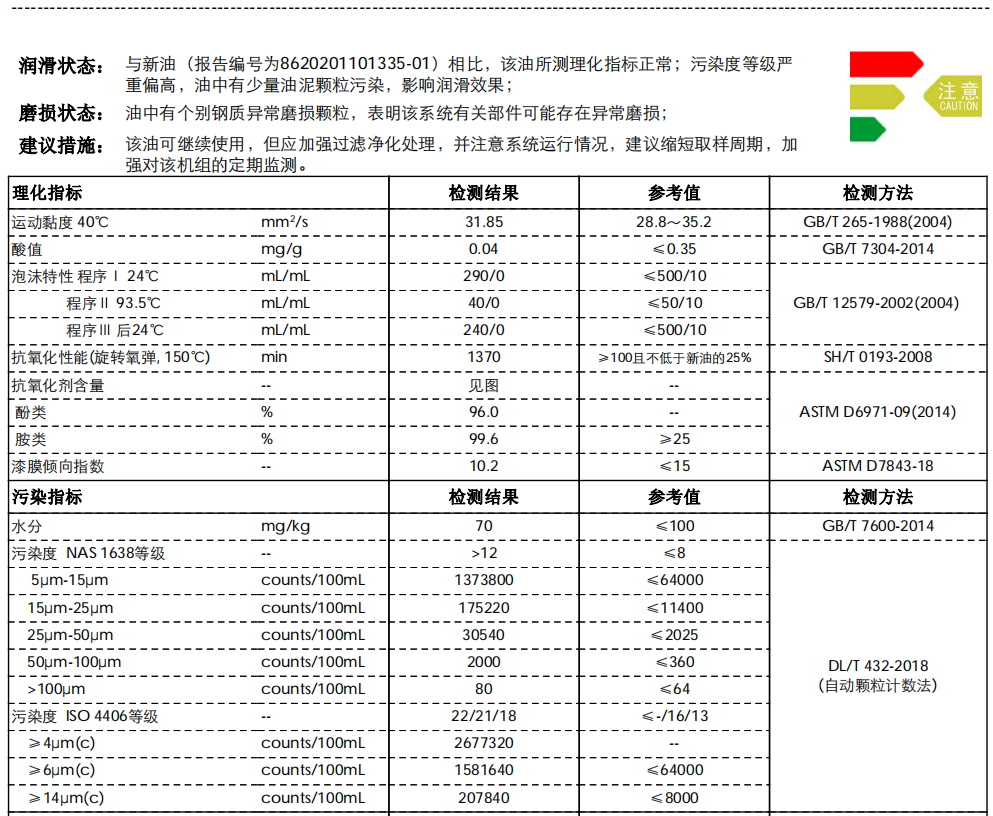

3.2.3 A ranar 23 ga Nuwamba, 2020, an aika da samfurin man mai na rukunin zuwa cibiyar gwaji ta Guangzhou Institute of Mechanical Science Co., Ltd. don gwaji da bincike.Ana nuna sakamakon a cikin Hoto 3. Sakamakon bincike ya gano cewa ƙimar MPC ta kasance mai girma, wanda zai iya ƙayyade abin da ya faru na man fetur.Furen yana daya daga cikin dalilan da ke haifar da yawan zafin jiki na tururin tururi mai ɗauke da TI31061B.Lokacin da aka sami varnish a cikin tsarin mai mai mai, rushewa da hazo na barbashi na varnish a cikin mai shine tsarin ma'auni mai ƙarfi saboda ƙarancin ikon mai mai mai don narkar da ɓarna.Lokacin da ya kai cikakkiyar yanayi, varnish zai rataye a kan kushin ɗaukar hoto, yana haifar da yanayin zafi mai ɗaukar nauyi.Babban haɗari ne na ɓoye ga aiki mai aminci.

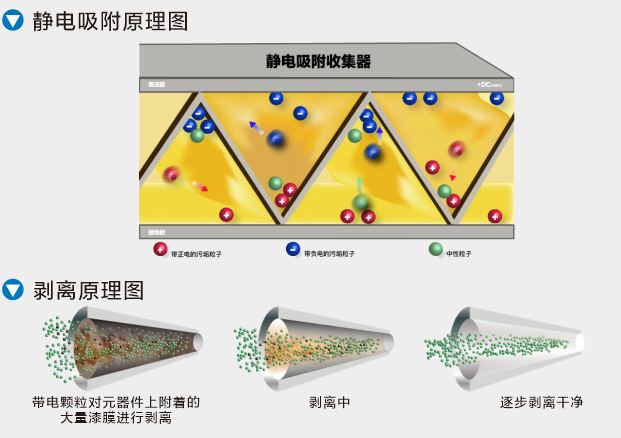

Ta hanyar bincike, mun zaɓi Kunshan Winsonda, wanda ya fi amfani da tasiri da kuma sunan kasuwa, don samar da WVD electrostatic adsorption + resin adsorption, wanda shine kayan aikin cirewa na varnish don kawar da varnish.

varnish wani samfur ne da aka samar ta hanyar lalatar mai, wanda ke wanzuwa a cikin mai a cikin narkar da ko dakatar da shi a ƙarƙashin wasu yanayin sinadarai da zafin jiki.Lokacin da sludge ya wuce solubility na mai mai mai, sludge zai yi hazo kuma ya samar da varnish a saman sashin.

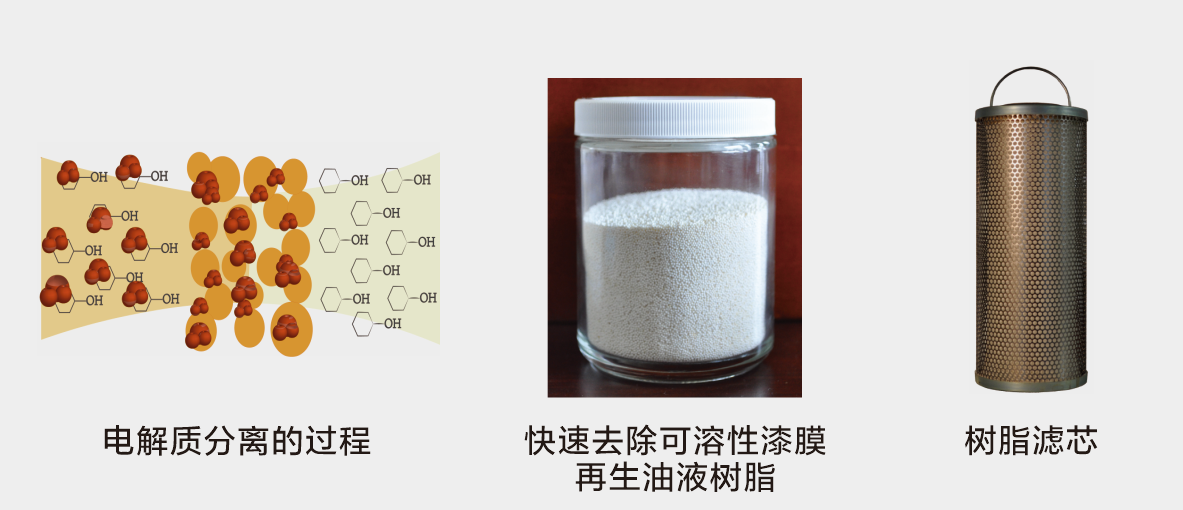

WVD-II jerin mai tsarkakewa yadda ya kamata hada electrostatic adsorption tsarkakewa fasahar da ion musayar fasahar, wanda zai iya yadda ya kamata cire da kuma hana mai narkewa da kuma insoluble sludge samar a lokacin al'ada aiki na turbi turbine, sabõda haka, da varnish ba za a iya samar.

Manufar WVD-II jerin masu tsabtace mai shine kawar da dalilin samuwar varnish.Wannan fasaha na iya rage abubuwan da ke cikin sludge a cikin ɗan gajeren lokaci, da kuma mayar da tsarin mai na asali tare da adadi mai yawa na sludge / varnish zuwa yanayin aiki mafi kyau a cikin 'yan kwanaki, don haka gaba daya warware matsalar jinkirin hawan zafin jiki na turawa. bearings lalacewa ta hanyar varnish .

Hoto 3 Sakamakon gwaji da bincike kafin shigar da sashin cire varnish

Mai tsabta mai tsabta na lokaci ɗaya: adsorption na electrostatic don cire sludge maras narkewa / varnish ka'ida: fasahar adsorption na electrostatic yana kawar da gurɓataccen abu, mai yana cikin aikin madauwari high-voltage electrostatic filin, don haka gurɓataccen barbashi ya nuna tabbatacce da kuma mummunan zargin bi da bi. , kuma a ƙarƙashin aikin filin lantarki na trapezoidal Tura abubuwan da aka caje masu kyau da kuma mummunan aiki don yin iyo zuwa ga ma'auni mai kyau da kuma tasiri, kuma ana matsawa tsaka-tsakin tsaka-tsakin kuma suna motsa su ta hanyar kwararar ƙwayoyin da aka caje, kuma a ƙarshe duk sassan suna adsorbed akan. mai tarawa ya cire gaba daya gurbataccen mai a cikin mai.

Na biyu mai tsabta mai tsabta: Ion musayar resin adsorption don cire narkar da colloid Ƙa'ida: Fasaha adsorption fasaha kadai ba za ta iya magance varnish da aka narkar da shi ba, yayin da resin ion ya ƙunshi biliyoyin shafukan yanar gizo na polar, wanda zai iya ɗaukar varnish mai narkewa da yuwuwar varnish, don tabbatar da cewa samfuran lalata sun yi. baya tarawa a cikin man mai mai, kuma yana iya inganta ƙoshin mai na mai, ta yadda tsarin ya kasance cikin yanayin aiki mafi kyau.

Hoto 5. Tsarin tsari na mai tsabta na biyu

3.3 Tasirin cire varnish

An shigar da sashin varnish kuma an yi aiki da shi a ranar 14 ga Disamba, 2020, kuma zafin injin turbine mai ɗauke da TI31061B ya ragu zuwa kusan 92°C a ranar 19 ga Disamba, 2020 (kamar yadda aka nuna a hoto 6).

Fig.6 Yanayin zafin jiki na turawa mai ɗauke da TI31061B na injin tururi

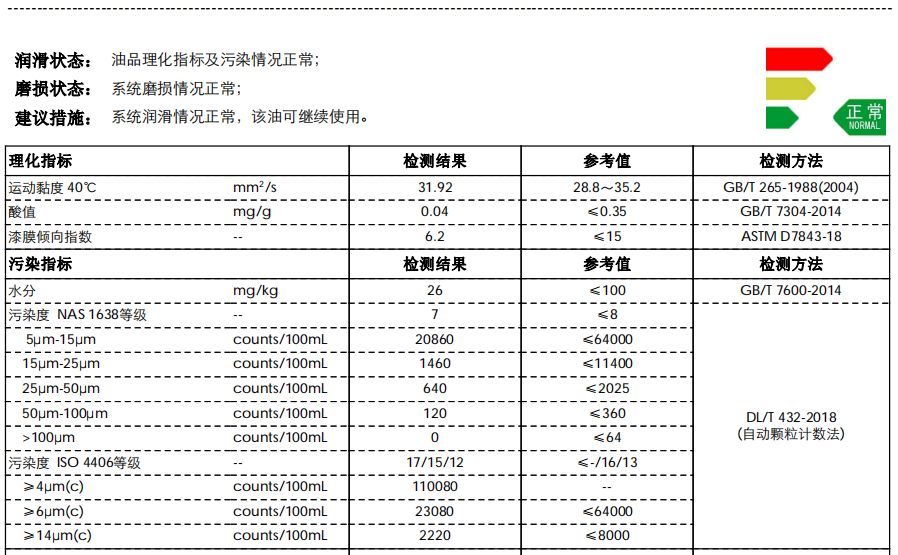

Bayan fiye da wata guda na aiki na sashin cirewar varnish, ingancin man lubricating na rukunin ya inganta sosai.Ta hanyar ganowa da bincike na Cibiyar Bincike ta Guangyan, an rage ma'aunin yanayin varnish na samfuran mai daga 10.2 zuwa 6.2, kuma an rage matakin gurɓatawa daga> 12 zuwa 7 Grade, babu asarar duk wani ƙari a cikin lubricating. mai (duba Hoto 7 don ganowa da sakamakon bincike bayan an shigar da sashin cire varnish).

FIG.7 Gwaji da sakamakon bincike bayan an shigar da naúrar

4 Fa'idodin tattalin arziki da aka samar

Ta hanyar shigarwa da aiki na sashin cirewar varnish, matsalar jinkirin hauhawar zafin jiki na turawa mai ɗauke da TI31061B na injin tururi wanda ke haifar da varnish gaba ɗaya an warware shi gaba ɗaya, kuma babbar asarar da ta haifar da rufe na'urar kwampreshin gas na pyrolysis shine. kaucewa (aƙalla kwanaki 3, asarar aƙalla RMB miliyan 4 ne; maye gurbin turɓayar turɓaya yana ɗaukar kwana 1, asarar shine miliyan 1), da asarar kayan gyara ga sassan juyawa da rufewa bayan haka. zafin jiki na matsa lamba yana ƙaruwa a hankali (asara tsakanin yuan miliyan 500,000 zuwa 8).

Na'urar ta cika da jimillar ganga 160 na kayayyakin mai, kuma kayayyakin man sun kai ga ma'aunin da suka dace, bayan da aka yi madaidaicin tace na'urar cire man fetir, inda aka ceci RMB 500,000 na farashin sauya kayan mai.

5 Kammalawa

Saboda yanayin zafi mai tsayi na dogon lokaci, matsa lamba, da yanayin aiki mai sauri a cikin tsarin lubrication na manyan raka'a, saurin iskar oxygen na man fetur yana haɓaka da haɓakar index na varnish.Haɗarin ɓoye na kona daji a cikin turawa yana tabbatar da aikin kwanciyar hankali na dogon lokaci na rukunin, wanda ke tabbatar da cewa matakan da ke sama suna da inganci.

Lokacin aikawa: Dec-28-2022