Sashen Gudanar da Kayan aiki, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Wannan takarda tana nazarin abubuwan da ba na al'ada ba na manyan raka'a masu fadada turbo, suna gabatar da jerin matakai don magance matsalolin, da kuma fahimtar abubuwan haɗari da matakan kariya na aiki.Ta hanyar aikace-aikacen fasahar cire varnish, ana kawar da haɗarin ɓoye masu yuwuwar kuma an tabbatar da amincin naúrar.

1. bayyani

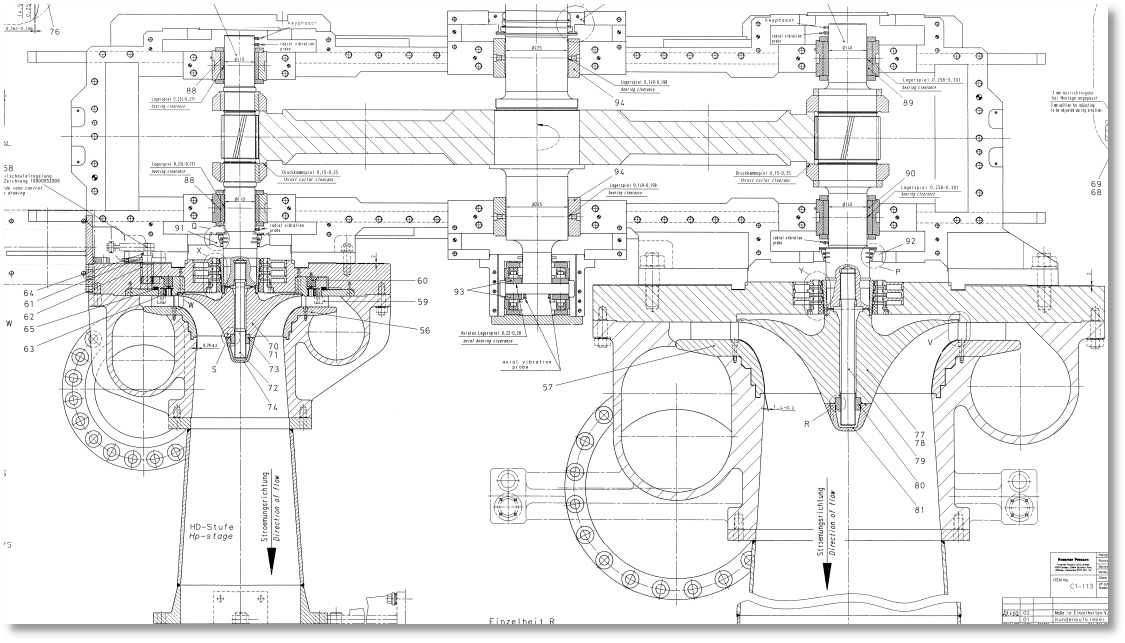

Naúrar damfara na iska na 60 t / a PTA shuka na Yizheng Chemical Fiber Co., Ltd. sanye take da kayan aiki daga Jamus MAN Turbo.Nau'in naúrar ce ta uku cikin ɗaya, wanda na'urar kwampreshin iska ta kasance nau'in injin turbine mai hawa biyar mai dumbin yawa, ana amfani da injin turbine mai ɗaukar nauyi a matsayin babban injin tuƙi na na'urar compressor na iska, kuma na'urar faɗaɗa turbo ita ce. ana amfani dashi azaman na'urar kwampreso.Injin tuƙi mai taimako.The turbo expander rungumi dabi'ar high da low mataki biyu fadada, kowane yana da tsotsa tashar jiragen ruwa da kuma shaye tashar jiragen ruwa, da kuma impeller rungumi dabi'ar na uku-hanya impeller (duba Hoto 1)

Hoto 1 Ra'ayin sashe na ɓangaren haɓakawa (hagu: babban matsa lamba; dama: ƙananan matsa lamba)

Babban ma'auni na aikin turbo expander sune kamar haka:

Matsakaicin matsakaicin matsakaicin matsakaici shine 16583 r / min, kuma saurin gefen ƙananan matsa lamba shine 9045 r / min;jimlar ƙarfin mai faɗaɗawa shine 7990 KW, kuma yawan kwarara shine 12700-150450-kg/h;Matsakaicin shigarwar shine 1.3Mpa, kuma matsin shayewa shine 0.003Mpa.Matsakaicin yawan zafin jiki na gefen matsa lamba shine 175 ° C, kuma yawan zafin jiki shine 80 ° C;yawan zafin jiki na gefen ƙananan matsa lamba shine 175 ° C, kuma yawan zafin jiki shine 45 ° C;ana amfani da saitin ɓangarorin karkatarwa a ƙarshen matsi mai ƙarfi da ƙananan ramuka na gear gears Bearings, kowanne da pads 5, bututun shigar mai na iya shiga mai ta hanyoyi biyu, kuma kowane ɗaki yana da rami mai shigar da mai guda ɗaya, ta hanyar. Rukunin 3 na nozzles na allurar mai guda 15, diamita na bututun shigar mai shine 1.8mm, Akwai ramukan dawo da mai guda 9 don ɗaukar nauyi, kuma a cikin yanayi na yau da kullun, ana amfani da tashoshi 5 da tubalan 4.Wannan rukunin uku cikin ɗaya yana ɗaukar hanyar lubrication tilas na samar da mai ta tsakiya daga tashar mai.

2. Matsaloli tare da ma'aikatan

A cikin 2018, don biyan buƙatun fitar da VOC, an ƙara sabon sashin VOC a cikin na'urar don kula da iskar gas ɗin wutsiya na reactor oxidation, kuma har yanzu ana allurar gas ɗin wutsiya a cikin na'urar.Saboda gishirin bromide a cikin iskar gas ɗin wutsiya na asali yana da iskar oxygen a babban zafin jiki, akwai ions bromide.Don hana ions bromide daga condensing da rabuwa a lokacin da wutsiya gas fadada da kuma aiki a cikin expander, zai haifar da pitting lalata ga expander da na gaba kayan aiki.Sabili da haka, ya zama dole don ƙara sashin haɓakawa.Zazzabi da zafin jiki na shaye-shaye na gefen babban matsi da ƙananan matsa lamba (duba Table 1).

Tebura 1 Jerin yanayin yanayin aiki a mashigai da mashigar mai faɗaɗa kafin da bayan canjin VOC

| A'A. | Canjin siga | Canji na tsohon | Bayan canji |

| 1 | Babban matsa lamba gefen shan zafin iska | 175 °C | 190 °C |

| 2 | Babban matsa lamba gefen shaye zafin jiki | 80 ℃ | 85 °C |

| 3 | Ƙaramar matsa lamba gefen shan zafin iska | 175 °C | 195 ° C |

| 4 | Low matsa lamba gefen shaye zafin jiki | 45 °C | 65 °C |

Kafin canjin VOC, zazzabi na gefen da ba mai motsa jiki ba a ƙarshen ƙarancin matsa lamba ya kasance mai ƙarfi a kusan 80 ° C (zazzabi na ƙararrawa a nan shine 110 ° C, kuma babban zafin jiki shine 120 ° C).Bayan da aka fara canjin VOC a ranar 6 ga Janairu, 2019, zazzabi na gefen da ba mai motsa jiki ba a ƙarshen ƙarshen matsi ya tashi sannu a hankali, kuma mafi girman zafin jiki yana kusa da mafi girman zazzabi da aka ruwaito na 120 ° C, amma sigogin girgiza ba su canza sosai ba a wannan lokacin (duba Hoto 2).

Hoto 2 Hoto na ƙimar kwarara mai faɗaɗawa da girgiza shaft ɗin mara tuƙi da zafin jiki

1 - Layin kwarara 2 - layin ƙarshen mara tuƙi 3 - layin girgiza shaft mara tuƙi

3. Sanadin bincike da hanyar magani

Bayan dubawa da kuma nazarin yanayin canjin yanayin zafi na turbine bearings, da kuma kawar da matsalolin nunin kayan aiki a kan wurin, canjin tsari, watsawar tururi mai goga, saurin saurin kayan aiki, da ingancin sassa, manyan dalilan da ke haifar da canjin yanayin zafi. su ne:

3.1 Dalilai na haɓakar zafin jiki na gefen da ba mai motsa jiki ba a ƙarshen ƙarancin matsi na faɗaɗa.

3.1.1 Binciken rarrabuwar kawuna ya gano cewa tazarar da ke tsakanin ɗaki da shaft da kuma share haƙoran gear sun kasance al'ada.Sai dai abin da ake zargi da varnish akan gefen gefen da ba mai motsa jiki ba a ƙaramin matsi na ƙarshen mai faɗaɗa (duba Hoto 3), ba a sami rashin daidaituwa ba a cikin wasu nau'ikan.

Hoto 3 Hoton jiki na madaidaicin ƙarewar mara tuƙi da nau'in motsi na mai faɗaɗa

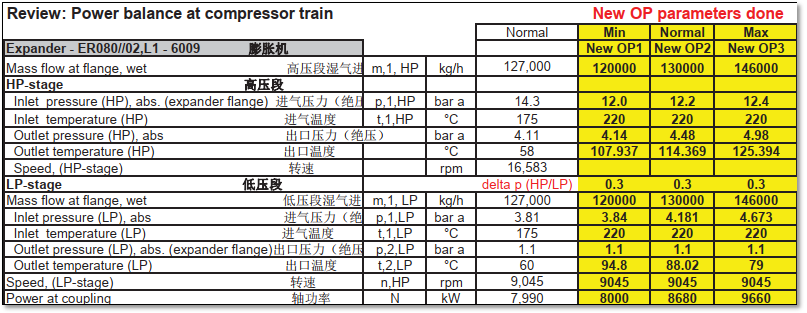

3.1.2 Tun lokacin da aka maye gurbin man mai na ƙasa da shekara guda, ingancin mai ya ci jarabawa kafin tuƙi.Don kawar da shakku, kamfanin ya aika da man mai ga ƙwararrun kamfani don gwadawa da bincike.Kamfanin ƙwararrun ya tabbatar da cewa abin da aka makala a kan abin da aka haɗe shi ne farkon varnish, MPC (ƙididdigar ƙididdiga na varnish) (duba Hoto 4)

Hoto 4 Rahoton nazarin fasahar sa ido kan mai da fasahar sa ido kan mai ta fitar

3.1.3 Man lubricating da ake amfani da shi a cikin mai faɗaɗa shine Shell Turbo No. 46 man turbine (man ma'adinai).Lokacin da man ma'adinai ya kasance a cikin zafin jiki mai zafi, mai mai mai ya zama oxidized, kuma samfuran oxidation suna taruwa a saman daji mai ɗaukar hoto don samar da varnish.Man lubricating na ma'adinai galibi ya ƙunshi abubuwa ne na hydrocarbon, waɗanda ba su da ƙarfi a yanayin zafi da ƙarancin zafi.Duk da haka, idan wasu (ko da ƙananan adadin) na kwayoyin halitta na hydrocarbon sun sami halayen iskar oxygen a yanayin zafi mai yawa, sauran kwayoyin halitta na hydrocarbon kuma za su fuskanci halayen sarkar, wanda shine halayyar halayen sarkar hydrocarbon.

3.1.4 Masu fasaha na kayan aiki sun gudanar da bincike a kusa da goyon bayan jikin kayan aiki, yanayin sanyi na bututun shigar da bututun mai, gano ƙwanƙwasa tsarin mai, da amincin binciken zafin jiki.Kuma ya maye gurbin saitin bearings a ƙarshen maras motsi na gefen ƙananan matsi na faɗaɗa, amma bayan tuki na wata guda, zafin jiki har yanzu ya kai 110 ℃, sannan akwai manyan canje-canje a cikin rawar jiki da zafin jiki.An yi gyare-gyare da yawa don kusanci da yanayin da aka riga aka tsara, amma kusan ba tare da wani tasiri ba (duba hoto 5).

Hoto na 5 Taswirar abubuwan da ke da alaƙa daga 13 ga Fabrairu zuwa 29 ga Maris

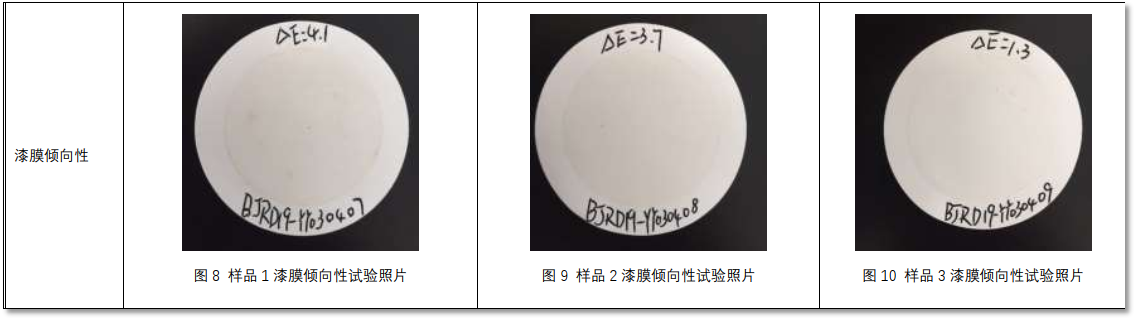

masana'anta MAN Turbo, a ƙarƙashin yanayin aiki na yanzu na faɗaɗa, idan ƙarar iska mai ɗaukar nauyi ta tsaya tsayin daka a 120 t / h, ƙarfin fitarwa shine 8000kw, wanda yake kusa da ƙirar ƙirar ƙirar asali na 7990kw a ƙarƙashin yanayin aiki na yau da kullun;Lokacin da ƙarar iska ta kasance 1 30 t / h, ƙarfin fitarwa shine 8680kw;idan ƙarar iska ta ci shine 1 46 t/h, ƙarfin fitarwa shine 9660kw.Tun da aikin da aka yi ta hanyar ƙananan ƙananan ƙididdiga na kashi biyu bisa uku na mai faɗakarwa, ƙananan ƙananan ƙananan ƙananan na iya zama da yawa.Lokacin da zafin jiki ya wuce 110 ° C, ƙimar girgiza yana canzawa sosai, yana nuna cewa sabon varnish ɗin da aka kafa akan saman shaft da daji mai ɗaukar hoto yana karce a wannan lokacin (duba Hoto 6).

Hoto 6 Teburin ma'auni na wutar lantarki na rukunin faɗaɗawa

3.2Binciken Injiniya na Matsalolin da suka wanzu

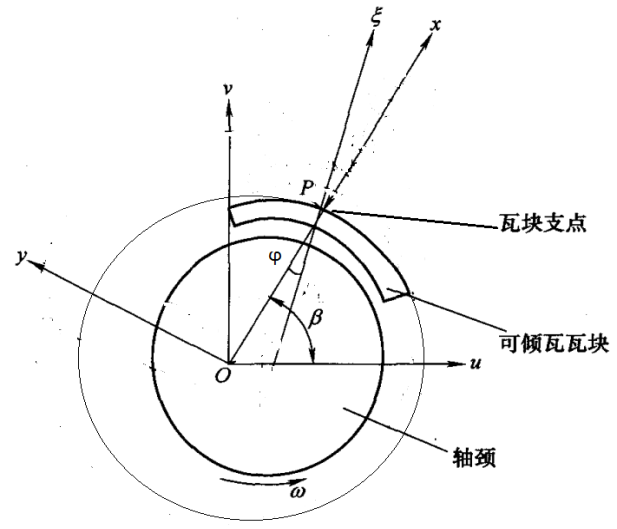

3.2.1 Kamar yadda aka nuna a cikin Hoto na 7, ana iya ganin cewa kusurwar da aka haɗa tsakanin ƙananan motsin motsi na fulcrum na tile block da layin daidaitawa a kwance a cikin tsarin haɗin gwiwar shine β, kusurwar juyawa na tile block shine φ , da kuma tsarin karkatar da kushin da ke tattare da tiles 5, lokacin da tayal Lokacin da pad ɗin ya kasance ƙarƙashin matsi na fim ɗin mai, tun da fulcrum na pad ɗin ba cikakke ba ne, matsayi na fulcrum na pad bayan nakasar matsawa zai kasance. samar da ƙaramin ƙaura tare da jagorar preload na geometric saboda taurin fulcrum, ta haka canza izinin ɗaukar kaya da kauri na fim mai [1]] .

Fig.7 Tsarin daidaitawa na kushin guda ɗaya na karkatar da kushin

3.2.2 Ana iya gani daga Hoto 1 cewa rotor shine tsarin katako na cantilever, kuma impeller shine babban bangaren aikin.Tun da gefen impeller shine gefen tuƙi, lokacin da iskar gas ya faɗaɗa don yin aiki, jujjuyawar jujjuyawar a gefen injin yana cikin yanayi mai kyau a cikin daji mai ɗaukar nauyi saboda tasirin dampler gas, kuma tazarar mai ta kasance al'ada.A cikin aiwatar da meshing da watsa juzu'i tsakanin manya da kanana gears, tare da wannan a matsayin fulcrum, radial free motsi na non impeller gefen shaft za a iyakance a karkashin obalodi yanayi, da kuma lubricating fim matsa lamba ya fi na sauran. bearings, yin wannan wuri mai lubricated Taurin fim ɗin yana ƙaruwa, ƙimar sabunta fim ɗin mai ya ragu, kuma zafi yana ƙaruwa, yana haifar da varnish.

3.2.3 Ana samar da varnish a cikin mai a cikin nau'i uku: mai da iskar shaka, mai "micro-combustion", da fitarwa mai zafi na gida.Ya kamata a yi amfani da varnish ta hanyar "micro-konewa" na man fetur.Hanyar ita ce kamar haka: wani adadin iska (gaba ɗaya ƙasa da 8%) za a narkar da shi a cikin man mai mai.Lokacin da aka wuce iyakar solubility, iskar da ke shiga mai za ta kasance a cikin mai a cikin nau'i na kumfa da aka dakatar.Bayan shigar da matsi, matsa lamba yana haifar da waɗannan kumfa don yin saurin matsawa adiabatic, kuma zafin jiki na ruwa yana tashi da sauri don haifar da adiabatic "micro-combustion" na mai, yana haifar da ƙananan ƙananan ƙwayoyin cuta.Wadannan insolubles polar ne kuma suna yin riko da saman karfe don samar da varnishs.Mafi girman matsa lamba, ƙananan solubility na al'amuran da ba a iya narkewa ba, kuma mafi sauƙi shi ne haɓakawa da daidaitawa don samar da varnish.

3.2.4 Tare da samuwar varnish, kauri na fim din mai a cikin jihar da ba ta da kyauta yana shagaltar da varnish, kuma a lokaci guda saurin sabuntawa na fim din mai ya ragu, kuma yawan zafin jiki ya tashi a hankali, wanda ya karu. rikice-rikicen da ke tsakanin saman daji mai ɗaukar hoto da ramin, da ƙoshin da aka ajiye yana haifar da ƙarancin zafi da hauhawar zafin mai zuwa babban zafin daji mai ɗaukar nauyi.A ƙarshe, jaridar ta shafa akan varnish, wanda ke nunawa a cikin tashin hankali a cikin girgizar shaft.

3.2.5 Ko da yake ƙimar MPC na mai faɗaɗawa ba ta da girma, lokacin da akwai varnish a cikin tsarin mai mai mai, rushewar da hazo na ɓangarorin varnish a cikin mai yana iyakance saboda ƙarancin ikon mai narkar da mai don narkewa. da varnish barbashi.Tsarin ma'auni ne mai ƙarfi.Lokacin da ya kai cikakkar yanayi, varnish zai rataya a kan abin da aka ɗaure ko ɗamara, wanda zai haifar da canjin yanayin zafi na kushin ɗaukar hoto, wanda shine babban ɓoyayyiyar haɗari da ke shafar aiki mai aminci.To amma saboda ya yi riko da kushin da aka yi amfani da shi, yana daya daga cikin dalilan da ke haifar da hauhawar zafin jiki.

4 Ma'auni da Ma'auni

Cire tarawar varnish a kan ɗaukar hoto na iya tabbatar da cewa ɗaukar naúrar yana gudana a yanayin zafi mai sarrafawa.Ta hanyar bincike da sadarwa tare da masana'antun da yawa na kayan aikin cire varnish, mun zaɓi Kunshan Winsonda, wanda ke da tasirin amfani mai kyau da kuma martabar kasuwa, don samar da WVD-II adsorption electrostatic adsorption + resin adsorption, wanda shine kayan aikin cirewa na fili don cire fenti.membrane.

WVD-II jerin mai tsarkakewa yadda ya kamata hada electrostatic adsorption fasahar tsarkakewa da fasahar musayar ion, warware narkar da varnish ta guduro adsorption, da kuma warware precipitated varnish ta electrostatic adsorption.Wannan fasaha na iya rage yawan abin da ke cikin sludge a cikin ɗan gajeren lokaci , A cikin ɗan gajeren lokaci na kwanaki da yawa, ana iya mayar da tsarin lubrication na asali wanda ke dauke da adadi mai yawa na sludge / varnish zuwa yanayin aiki mafi kyau, da kuma matsalar jinkirin tashi a cikin. Za'a iya magance zafin daɗaɗɗen turawar da varnish ya haifar.Yana iya cirewa yadda ya kamata kuma ya hana sludge mai mai narkewa da mara narkewa wanda aka haifar yayin aiki na yau da kullun na turbine.

Babban ka'idojinsa sune kamar haka:

4.1 Ion musayar guduro don cire narkar da varnish

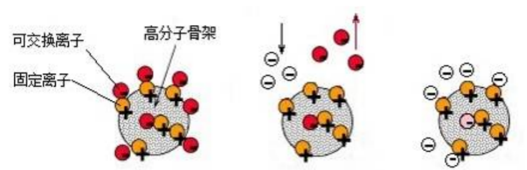

Ion musayar guduro yafi hada da sassa biyu: polymer skeleton da ion musayar kungiyar.An nuna ka'idar tallata a cikin hoto 8,

Hoto 8 Ka'idar ion-interaction resin adsorption

An raba ƙungiyar musayar zuwa ƙayyadaddun yanki da ɓangaren motsi.Ƙaƙƙarfan ɓangaren da aka ɗaure akan matrix polymer kuma ba zai iya motsawa cikin yardar kaina ba, kuma ya zama ƙayyadaddun ion;ɓangaren motsi da ƙayyadaddun ɓangaren ana haɗa su ta hanyar haɗin gwiwar ionic don zama ion mai canzawa.Kafaffen ions da ions na wayar hannu suna da sabani na caji.A cikin daji mai ɗaukar nauyi, sashin wayar hannu yana bazuwa cikin ions masu motsi da yardar rai, waɗanda ke musayar tare da sauran samfuran lalata tare da caji iri ɗaya, don haɗa su tare da ƙayyadaddun ions kuma an ɗora su da ƙarfi akan tushen musayar.A kan rukunin, an ɗauke ta da man fetur, narkar da varnish cire ta hanyar ion musayar resin adsorption.

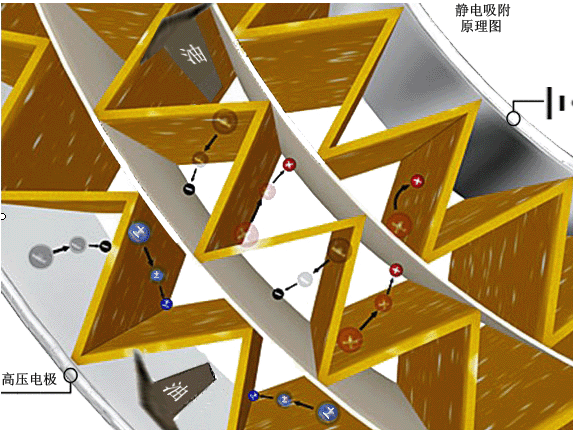

4.2 Fasaha adsorption na Electrostatic don cire varnish da aka dakatar

Fasahar adsorption ta Electrostatic galibi tana amfani da janareta mai ƙarfi don samar da filin lantarki mai ƙarfin ƙarfin lantarki don sanya gurɓataccen barbashi a cikin mai don nuna caji mai kyau da mara kyau bi da bi.Ana matse ɓangarorin tsaka tsaki ana motsa su ta hanyar ɓangarorin da aka caje, kuma a ƙarshe an haɗa dukkan ɓangarorin kuma an haɗa su da mai tarawa (duba hoto na 9).

Hoto 8 Ka'idar fasahar adsorption electrostatic

Fasahar tsabtace mai na Electrostatic na iya cire duk abubuwan da ba za a iya narkewa ba, gami da ƙazantattun ƙazanta da kuma dakatar da varnish da aka samar ta hanyar lalata mai.Koyaya, abubuwan tacewa na gargajiya suna iya cire manyan barbashi tare da daidaitattun daidaitattun abubuwa, kuma yana da wahala a cire submicron. matakin dakatar da varnish .

Wannan tsarin zai iya magance gaba ɗaya varnish da aka haɗe kuma an ajiye shi akan kushin ɗaukar nauyi, ta haka gaba ɗaya warware tasirin zafin kushin ɗaukar hoto da sauye-sauyen girgizar da varnish ya haifar, ta yadda rukunin zai iya yin aiki da ƙarfi na dogon lokaci.

5 Kammalawa

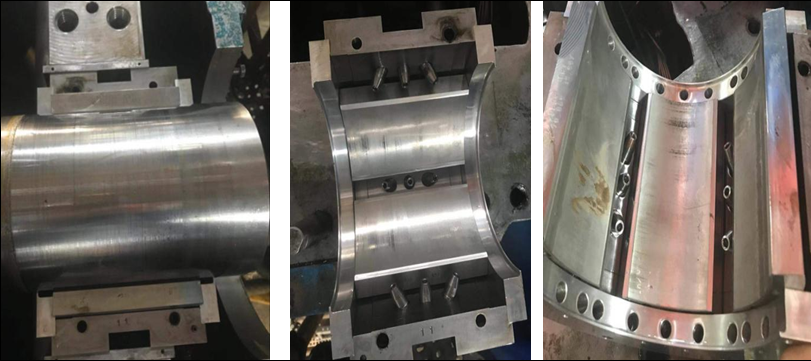

WSD WVD-II an yi amfani da naúrar cire varnish, ta hanyar lura da aiki na shekaru biyu, ana kiyaye yawan zafin jiki a kusan 90 ° C, kuma sashin yana ci gaba da aiki na yau da kullun.An samo fim ɗin varnish (duba hoto na 10).

Hoton jiki na ɗaukar rarrabuwa bayan shigar da cirewar varnish

kayan aiki

ambaton:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, da Chen Zhujie.Kwaikwayo na lamba da bincike na gwaji akan halaye masu ƙarfi na pivot roba da damping tilting pad bearings [J].Jaridar Sinanci na Injiniya, Oktoba 2014, 50 (19):88.

Lokacin aikawa: Dec-13-2022